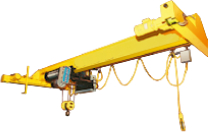

Single Girder cranes are typically the most cost efficient electric crane to put into service. We build both top running and underhung cranes with the former being the most popular. A top running crane has the bridge beam sitting on top of the end trucks with an underhung hoist where as an underhung/running crane hangs from the end trucks which ride under the runway beam, it too has an underhung hoist. Our single girder cranes range from 1 ton capacity up to 20 ton capacity with spans up to 60’ using wide flange girders and the capability to go up to 75’ using a box girder design. One of the reasons Crane Systems Inc has grown to the company we are today is because of how efficient we are with manufacturing single girder cranes. For cranes in 5 and 10 ton capacities with 25’ of lift and spans up to 60’ we have the capability to offer quick ship which guarantees a 3 week delivery from the time the order is placed. When headroom, capacity and span is not a problem a single girder crane will be the most economical.

Single Girder cranes are typically the most cost efficient electric crane to put into service. We build both top running and underhung cranes with the former being the most popular. A top running crane has the bridge beam sitting on top of the end trucks with an underhung hoist where as an underhung/running crane hangs from the end trucks which ride under the runway beam, it too has an underhung hoist. Our single girder cranes range from 1 ton capacity up to 20 ton capacity with spans up to 60’ using wide flange girders and the capability to go up to 75’ using a box girder design. One of the reasons Crane Systems Inc has grown to the company we are today is because of how efficient we are with manufacturing single girder cranes. For cranes in 5 and 10 ton capacities with 25’ of lift and spans up to 60’ we have the capability to offer quick ship which guarantees a 3 week delivery from the time the order is placed. When headroom, capacity and span is not a problem a single girder crane will be the most economical.

- Single Girder Cranes up to Class D

- GENERAL

- Up to 20 ton and 60' span using wide flange girders

- Up to 20 ton and 120' span using box girders

- Top running and Underhung

- Quick ship available for 5 and 10 ton with 25' lift

- CMAA Class C and D service

- Built to meet CMAA Specification #70, Revised 2004

- Electric, Air and explosion proof application available

- Festooned pushbutton standard

- Lowest impact on wheel load which saves on building material

- CONTROLS

- Adjustable variable frequency drives are a standard unless specified

- Motor Thermal overload protection - reduces possible motor damage

- Quick stop - reduces possibility of crane collision

- UL recognized electric thermal overload

- Dynamic braking resistors

- Clearly marked wires at both ends

- NEMA 4/12 enclosure

- 2 year warranty on parts

- HOISTS/TROLLEY

- Wire rope and chain hoists available

- Single and double reeved hoist available

- Single speed, 2-speed and Variable speed available

- Mechanical load brake available upon request

- Upper/Lower geared limit switch is standard

- END TRUCK

- Rotating or fixed axle

- The end truck frame consists of a tubular steel.

- Truck end plates serve as rail sweeps and shock absorbing bumpers.

- Double flanged wheels with hardened treads are mounted on rotating axles made of forged steel

- Ball or roller bearings are used based on wheel loading.

- Maximum rail size is dependent upon wheel diameter and capacity.

- A4 dual drives as a standard

- BRIDGE

- Standard structual shape or fabricated box

- Polyurethane bumpers are standard